INTRODUCTION

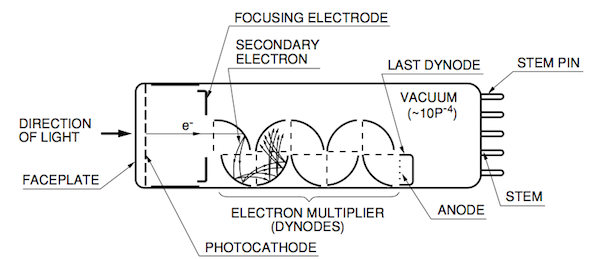

Among the photosensitive devices

in use today, the photomultiplier tube (or PMT) is a versatile device that

provides extremely high sensitivity and ultra-fast response. A typical

photomultiplier tube consists of a photoemissive cathode (photocathode) followed

by focusing electrodes, an electron multiplier and an electron collector (anode) in

a vacuum tube.When light enters the photocathode, the

photocathode emits photoelectrons into the vacuum. These photoelectrons are

then directed by the focusing electrode voltages towards the electron multiplier

where electrons are multiplied by the process of secondary emission. The multiplied

electrons are collected by the anode as an output signal. Because of

secondary-emission multiplication, photomultiplier tubes provide extremely high

sensitivity and exceptionally low noise among the photosensitive devices

currently used to detect radiant energy in the ultraviolet, visible, and near

infrared regions. The photomultiplier tube also features fast time response, low

noise and a choice of large photosensitive areas.

HISTORY

In 1935, Iams succeeded in producing a triode

photomultiplier tube with a photocathode combined with a single-stage dynode

(Secondary emissive surface), which was used for movie sound pickup. In the

next year 1936, Zworykin developed a

photomultiplier tube having multiple dynode stages. This tube enabled electrons

to travel in the tube by using an electric field and a magnetic field.Then, in

1939, Zworykin and Rajchman developed an electrostatic-focusing type

photomultiplier tube (this is the basic structure of photomultiplier tubes

currently used). In this photomultiplier tube, an Ag-O-Cs photocathode was

first used and later an Sb-Cs photocathode was employed.An improved

photomultiplier tube structure was developed and announced by Morton in 1949) and

in 1956. Since then the dynode structure has been intensively studied, leading

to the development of a variety of dynode structures including circular-cage,

linear-focused and box-and-grid types. In addition, photomultiplier tubes using

magnetic-focusing type multipliers transmission-mode secondary-emissive

surfaces and channel type multipliers have been developed.

CONSTRUCTION

A

photomultiplier tube is a vacuum tube consisting of an input window, a photocathode,

focusing electrodes, an electron multiplier and an anode usually sealed into an

evacuated glass tube. Figure shows the schematic construction of a

photomultiplier tube.

Light

which enters a photomultiplier tube is detected and produces an output signal

through the following processes.

(1)

Light passes through the input window.

(2)

Light excites the electrons in the photocathode so that photoelectrons are

emitted into the vacuum (external photoelectric effect).

(3)

Photoelectrons are accelerated and focused by the focusing electrode onto the

first dynode where they are multiplied by means of secondary electron emission.

This secondary emission is repeated at each of the successive dynodes.

(4)

The multiplied secondary electrons emitted from the last dynode are finally

collected by the anode.

The photomultiplier tube

generally has a photocathode in either a side-on or a head-on configuration.

The side-on type receives incident light through the side of the glass bulb,

while in the head-on type, it is received through the end of the glass bulb. In

general, the side-on type photomultiplier tube is relatively low priced and

widely used for spectrophotometers and general photometric systems. Most of the

side-on types employ an opaque photocathode (reflection-mode

photocathode) and a circular cage structure electron multiplier which has good

sensitivity and high amplification at a relatively low supply voltage.

The

head-on type (or the end-on type) has a semi transparent photocathode (transmission-mode

photocathode) deposited upon the inner surface of the entrance window.

The head-on type provides better

spatial uniformity than the side-on type having a reflection-mode photocathode.

Other features of head-on types include a choice of photosensitive areas from

tens of square millimetres to hundreds of square centimetres .

Variants of the head-on type

having a large-diameter hemispherical window have been developed for high

energy physics experiments where good angular light acceptability is important.

External appearance

Types of

Photocathode

WORKING

The superior sensitivity (high

current amplification and high S/N ratio) of photomultiplier tubes is due to

the use of a low-noise electron multiplier which amplifies electrons by a

cascade secondary electron emission process. The electron multiplier consists of

from 8, up to 19 stages of electrodes called dynodes.There are several

principal types in use today.

1)

Circular-cage type

The circular-cage is generally

used for the side-on type of photomultiplier tube. The prime features of the

circular-cage are compactness and fast time response.

2)

Box-and-grid type

This type consists of a train of

quarter cylindrical dynodes and is widely used in head-on type photomultiplier

tubes because of its relatively simple dynode design and improved uniformity,

although time response may be too slow in some applications.

3)

Linear-focused type

The linear-focused type features

extremely fast response time and is widely used in head-on type photomultiplier

tubes where time resolution and pulse linearity are important.

4) Venetian

blind type

The venetian blind type has a

large dynode area and is primarily used for tubes with large photocathode

areas. It offers better uniformity and a larger pulse output current. This structure

is usually used when time response is not a prime consideration.

5) Mesh type

The mesh type has a structure of

fine mesh electrodes stacked in close proximity. This type provides high

immunity to magnetic fields, as well as good uniformity and high pulse linearity.

In addition, it has position-sensitive capability when used with cross-wire

anodes or multiple anodes.

6)

Microchannel plate (MCP)

The MCP is a thin disk consisting

of millions of micro glass tubes (channels) fused in parallel with each other.

Each channel acts as an independent electron multiplier. The MCP offers much

faster time response than the other discrete dynodes.It also features good

immunity from magnetic fields and two-dimensional detection ability when

multiple anodes are used.

7) Metal

channel type

The Metal channel dynode has a

compact dynode costruction manufactured by our unique fine machining technique.It

achieves high speed response due to its narrower space between each stage of

dynodes than the other type of conventional dynode construction. It is also

adequate for position sensitive measurement.

The photocathode is a

photoemissive surface usually consisting of alkali metals with very low work

functions. The photocathode materials most commonly used in photomultiplier

tubes are as follows:

The transmission-mode

photocathode using this material is designated S-1 and sensitive from the

visible to infrared range (300 to 1200nm). Since Ag-O-Cs has comparatively high

thermionic dark emission, tubes of this photocathode are mainly used for

detection in the near infrared region with the photocathode cooled.

GaAs activated in

cesium is also used as a photocathode. The spectral response of this

photocathode usually covers a wider spectral response range than multi alkali,

from ultraviolet to 930nm, which is comparatively flat over 300 to 850nm.

This photocathode has

greater extended sensitivity in the infrared range than GaAs. Moreover, in the

range between 900 and 1000nm, InGaAs has much higher S/N ratio than Ag-O-Cs.

This is a widely used

photocathode and has a spectral response in the ultraviolet to visible range.

This is not suited for transmission-mode photocathodes and mainly used for

reflection-mode photocathodes.

5)

Bialkali (Sb-Rb-Cs, Sb-K-Cs)

These have a spectral

response range similar to the Sb-Cs photocathode, but have higher sensitivity

and lower noise than Sb-Cs. The transmission mode bialkali photocathodes also

have a favorable blue sensitivity for scintillator flashes from NaI (Tl)

scintillators, thus are frequently used for radiation measurement using

scintillation counting.

6)

High temperature bialkali or low noise bialkali (Na-K-Sb)

This is particularly

useful at higher operating temperatures since it can withstand up to 175°C.

A major application is in the oil well logging industry. At room temperatures,

this photocathode operates with very low dark current, making it ideal for use

in photon counting applications.

7)

Multialkali (Na-K-Sb-Cs)

The multialkali

photocathode has a high, wide spectral response from the ultraviolet to near

infrared region. It is widely used for broad-band spectrophotometers. The long

wavelength response can be extended out to 930nm by special photocathode

processing.

These materials are

sensitive to vacuum UV and UV rays but not to visible light and are therefore

called solar blind. Cs-Te is quite insensitive to wavelengths longer than

320nm,and Cs-I to those longer than 200nm.

The window materials

commonly used in photomultiplier tubes are as follows:

This is frequently

used glass material. It transmits radiation from the near infrared to

approximately 300nm. It is not suitable for detection in the ultraviolet

region. For some applications,the combination of a bialkali photocathode and a low-noise

borosilicate glass (so called K-free glass) is used.The K-free glass contains

very low potassium (K2O) which can cause background counts by 40K. In

particular, tubes designed for scintillation counting often employ K-free glass

not only for the faceplate but also for the side bulb to minimize noise pulses.

2)

UV-transmitting glass (UV glass)

This glass transmits

ultraviolet radiation well, as the name implies, and is widely used as a

borosilicate glass. For spectroscopy applications, UV glass is commonly used.

The UV cut-off is approximately 185nm.

The synthetic silica

transmits ultraviolet radiation down to 160nm and offers lower absorption in

the ultraviolet range compared to fused silica. Since thermal expansion

coefficient of the synthetic silica is different from Kovar which is used for the

tube leads, it is not suitable for the stem material of the tube . Borosilicate

glass is used for

the stem, then a

graded seal using glasses with gradually different thermal expansion

coefficients are connected to the synthetic silica window. Because of this

structure, the graded seal is vulnerable to mechanical shock so that sufficient

care should be taken in handling the tube.

4)

MgF2 (magnesium fluoride)

The crystals of

alkali halide are superior in transmitting ultraviolet radiation, but have the

disadvantage of deliquescence. Among these, MgF2 is known as a practical window

material because it offers low deliquescence and transmits ultraviolet

radiation down to 115nm.

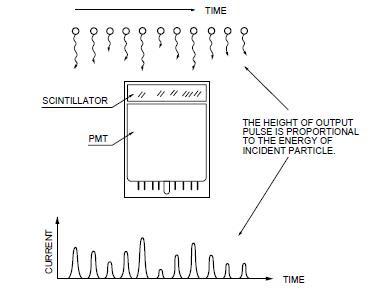

Scintillation

counting is one of the most sensitive and effective methods for detecting

radiation. It uses a photomultiplier tube coupled to a transparent crystal

called scintillator which produces light by incidence of radiation.

In radiation measurements, there

are two parameters that should be measured. One is the energy of individual

particles and the other is the amount of particles. Radiation measurements should

determine these two parameters.

When radiation enters the

scintillator, it produce light flashes in response to each particle. The amount

of flash is proportional to the energy of the incident racliation. The photomultiplier

tube detects individual light flashes and provides the output pulses which contain information on both

the energy and amount of pulses, as shown in Figure . By analyzing these output

pulses using a multichannel analyzer (MCA), a pulse height distribution (PHD)

or energy spectrum is obtained, and the amount of incident particles at various

energy levels can be measured accurately.

Typical PHDs or

energy spectra when gamma rays (55Fe, 137Cs, 60Co) are detected by the

combination of an NaI(Tl) scintillator and a photomultiplier tube. For the PHD,it

is very important to have distinct peaks at each energy level.This is evaluated

as pulse height resolution (energy resolution)and is the most significant

characteristic in radiation particle measurements.

References :

1. Photomultipier tubes basics and application (third edition), HAMAMATSU

2. Photomultiplier tubes construction and operating characteristics,HAMAMATSU